As electric motorcycles gain popularity, the motor controller becomes a vital component responsible for regulating power delivery between the battery and motor. It determines how smoothly the vehicle accelerates, how efficiently it uses energy, and how reliably it responds to rider input. This article outlines the structure of a typical motor controller, common signs of failure, diagnostic steps, and practical solutions for ensuring long-term performance.

Basic Structure and Function of the Motor Controller

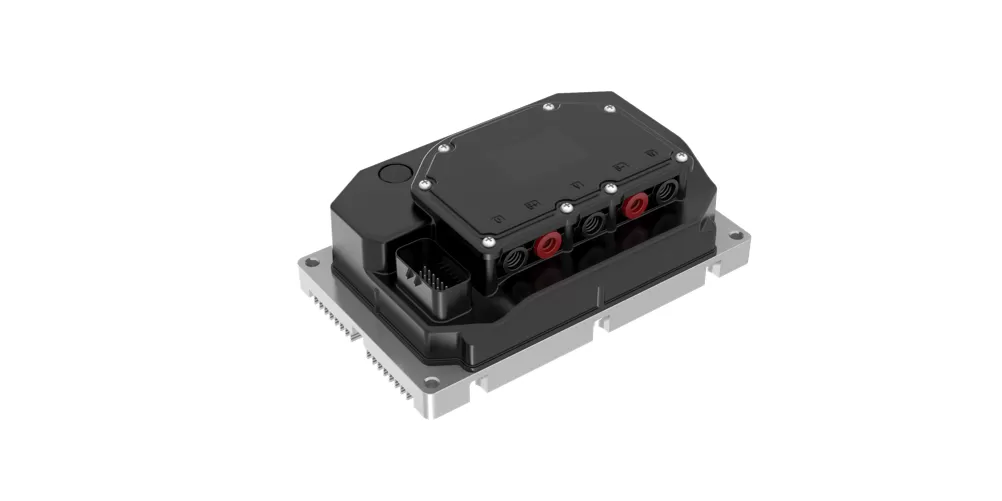

Before diving into faults, it’s important to understand how the motor controller works. Typically, it consists of a power stage (using MOSFETs or IGBTs), a microcontroller for signal processing, and input/output terminals for communication with the battery, motor, throttle, and brake systems.

The controller interprets signals from the throttle and other sensors, then adjusts voltage and current to the motor based on riding demands. This process requires precise coordination between hardware and software, making the controller a critical yet complex element in the drivetrain.

Common Symptoms of Controller Malfunction

Identifying controller faults early can prevent more serious issues. Here are the most frequently observed symptoms:

1. Motorcycle Fails to Start

If the system is powered on but the motor doesn’t respond, the controller might not be receiving or processing the start signal. Check the throttle signal, main power input, and communication wiring for faults.

2. Unstable Acceleration or Jerking

Inconsistent throttle response or jerky movement may indicate software miscalibration, poor signal processing, or intermittent electrical contact inside the controller.

3. Overheating of the Controller

While some heat is expected, abnormal temperature rise suggests issues such as overcurrent conditions, inefficient heat dissipation, or internal component degradation.

4. Error Codes on Display

Modern electric motorcycles often provide fault codes on their dashboards. Controller-related errors might include “overvoltage,” “phase error,” or “communication failure,” depending on the manufacturer’s design.

5. Sudden Power Cut While Riding

Abrupt loss of power may point to short circuits, thermal shutdown mechanisms, or protective logic triggered by abnormal input signals.

Routine Diagnosis and Preventive Maintenance

Proactive maintenance is essential for controller reliability. The following practices can help reduce failure risk:

- Inspect Wiring and Connectors Regularly: Look for loose terminals, corrosion, or damaged insulation, especially in high-vibration areas.

- Monitor Operating Temperature: Use built-in sensors or IR thermometers to track controller heat, particularly during long rides or uphill climbs.

- Firmware Updates: Ensure that the controller’s firmware is up to date if it supports digital upgrades. New versions may fix known bugs and improve stability.

- Avoid Moisture Exposure: Though many controllers are sealed, prolonged exposure to water or high humidity can degrade seals and lead to internal corrosion.

Troubleshooting Methods for Controller Failures

When controller issues arise, use a step-by-step diagnostic approach:

- Check Battery and Voltage Input: Confirm the battery voltage matches the controller’s requirements. Low voltage can mimic controller faults.

- Examine Signal Inputs: Use a multimeter or diagnostic tool to check throttle, brake, and speed sensor signals for abnormalities.

- Test Motor Phase Connections: Incorrect phase wiring or damaged cables can cause controller protection shutdowns or poor performance.

- Replace Suspected Components: If tests confirm controller failure, replace it with a compatible unit. Be sure to match voltage, current, and communication protocols.

- Seek Manufacturer Support: For advanced diagnostics, consult the controller supplier’s technical team for assistance or send the unit for bench testing.

Understanding Controller Overheating

Controller overheating is a frequent challenge, especially during high-load conditions. Key contributing factors include:

- Excessive Current Demand: Steep inclines or heavy loads may push the controller beyond safe limits.

- Inadequate Cooling Design: Poor placement or lack of airflow around the controller enclosure impedes heat dissipation.

- Component Wear: Aging MOSFETs, thermal pads, or cooling fans degrade performance over time.

To address overheating:

- Reduce Load Conditions: Avoid aggressive acceleration or overloading the motorcycle.

- Improve Cooling: Use heat sinks, cooling fans, or ensure controller placement allows for adequate ventilation.

- Maintain Clean Surfaces: Dust and grime on the controller casing can hinder passive cooling.

Conclusion

The motor controller is the brain of an electric motorcycle’s powertrain, and its proper function is crucial for performance and safety. By recognizing early signs of failure, conducting regular inspections, and applying appropriate troubleshooting techniques, riders and technicians can ensure long-lasting reliability. For advanced motor controller solutions designed for precision and durability, GTAKE offers industry-proven technologies tailored for electric two-wheelers. Contact GTAKE today to learn how our controller systems can power your success.